Pour-in-Place Surfacing - What You Need to Know

Site Preparation

Area must be excavated to remove all organic materials that will decompose, settle, & affect surfacing

Drainage must be addressed as safety surfacing is porous

Suitable sub-base & edging installed (options below)

ADA compliant grading needed

Sub-base Options:

Crushed Aggregate – Comprised of a 4” minimum of 3/4” crushed stone

Concrete – Existing concrete must be free from major cracks & damage. New concrete must have a minimum of 14 days to cure.

Asphalt – Existing Asphalt must be free of any major cracks & damage. New Asphalt must have a minimum of 30 days to cure & must be power washed 3 separate times

Edging Options (Borders):

A. Concrete

B. Treated Timbers

C. Rubber Curbs

D. Beveled Edge- Angling surfacing down to grade (can't be done with stone)

E. Turn Down Edge- Angling surfacing down below grade, to be later back-filled by EWF, grass, etc. *PIP will not adhere to plastic timbers*

About the PIP System

Thickness of surfacing is dependent on the fall height of the play equipment

Wear course is made of TPV, cushion layer is made of Chunk (pre-consumer, post-industrial rubber)

Wear course only installations (no attenuating layer) must be installed over asphalt or concrete

Areas within the use zone of equipment must contain safety surfacing (communicated in square footage)

Urethane Options:

A. Aromatic (Standard, subject to amber)*

B. Aliphatic (Premium, does not amber)

*Ambering effect is temporary & mechanically wears off over time. It is an issue with aesthetics but does not hurt or compromise the longevity of the rubber.

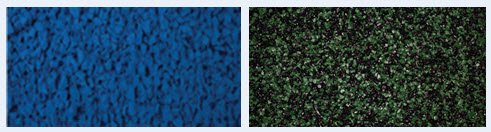

Color Blends:

50/50 color is most popular (50% colored granules, 50% black granules)

Other blends include 75%/25%, 33/33/33, etc., up to 100% color.

Black/Colored granules are different types of rubber,

higher color concentration leads to a stronger surface (50% black is the max)

Maintenance/Installation of PIP Surface

Routine cleaning of debris on surface, power washing when necessary, Using approved products to clean surfacing. Work performed by owner

Maintenance spray coating strengthens the urethane bond of the pad, Makes existing colors more prevalent and increases longevity. Recommended every 3-5 years based on use. Work is performed professionally.

Repair options include patch repairs, seam repairs, perimeter repairs, or ½” wear course re-tops. Work is performed professionally.

50° and rising and no precipitation needed for installation. 70° for aliphatic.

For more information about pour-in-place rubber surfacing, please contact us.